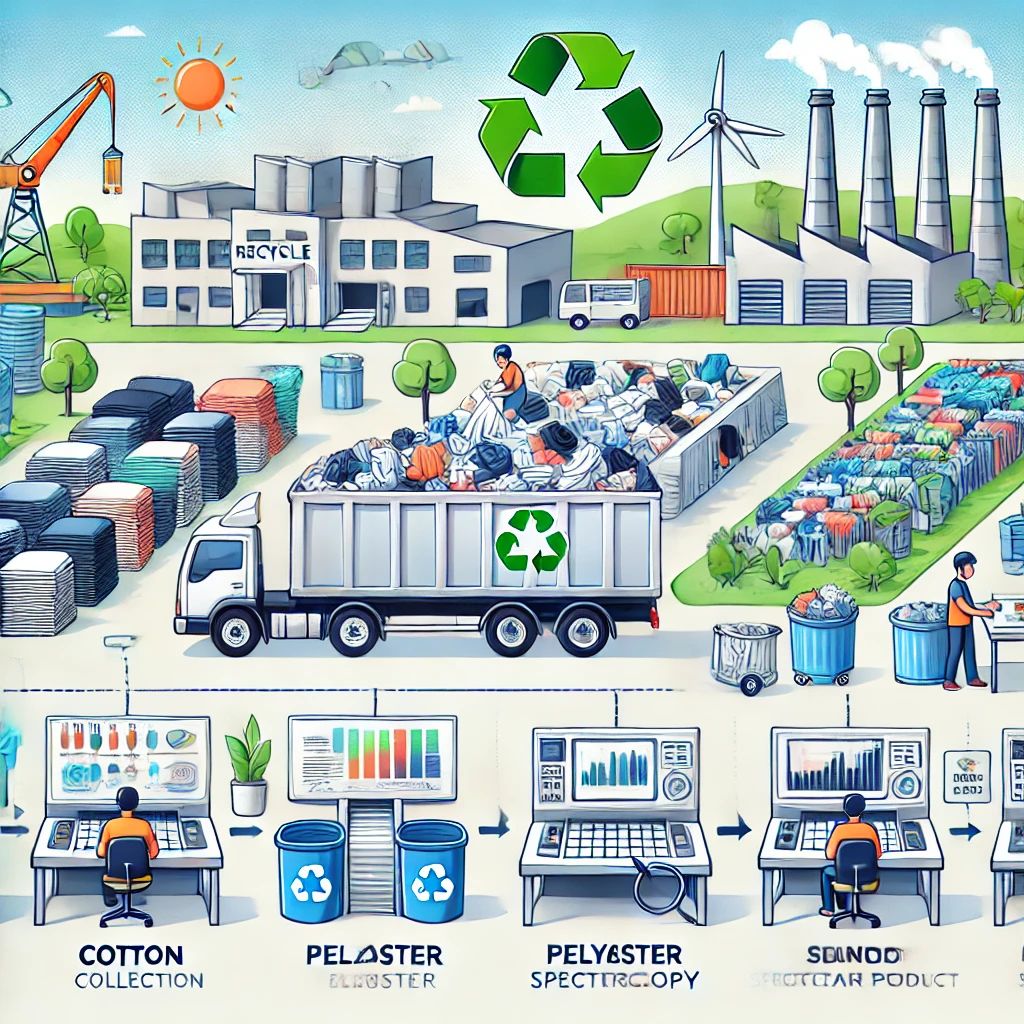

In recent years, the textile industry in India has been undergoing a quiet but significant transformation. At the heart of this change is the increasing focus on recycling textiles — a critical step toward building a circular economy and reducing the environmental footprint of fashion and hospitality industries. One fascinating example is how innovative models are being built around the collection and processing of used textiles from large institutions such as hotels.

Building a Collection Ecosystem: The Bangalore Model

The process began in Bangalore, where dedicated systems were developed for collecting used towels and textiles from hotels and institutional clients. Establishing strong relationships with hotels was the foundation, but the real breakthrough came from partnering with regional waste management companies. These companies were not just collection agents; they became trained representatives who ensured that sorting was done meticulously according to different material categories and quality grades.

Training sorters was crucial — they needed to recognize subtle differences in textile types, fiber quality, and blend composition. This classification impacts the value chain, as different categories of textiles are priced differently and are suitable for distinct recycling outcomes.

Why 100% Cotton Matters

In the Indian textile recycling industry, 100% cotton is highly prized. This fiber is easier to recycle and can be re-spun into new yarns or turned into other products with minimal degradation. Unfortunately, blends — especially those mixing cotton with synthetic fibers — present more complexity. While these blends are more difficult to process, innovation is helping to close the gap.

Technology Stepping In

One exciting development has been the use of near-infrared (NIR) spectroscopy for fiber identification. Companies like Matoa are using this technology to quickly and accurately scan textiles and identify fiber composition within milliseconds. While these machines are incredibly accurate when dealing with pure fibers like 100% cotton or polyester, the challenge remains with blended fabrics. However, advances are being made, and accuracy is improving year by year.

Another promising innovator in this space is Kosha, an Indian startup developing machines designed to further enhance blend detection accuracy. This innovation not only makes recycling more effective but also makes the supply chain more transparent and efficient.

The Investment Challenge

Technology adoption in textile recycling is promising, but not without barriers. The most significant among them is funding. While large-scale recyclers may afford cutting-edge equipment, smaller waste management companies often lack the resources to invest in this technology. The industry needs targeted investment and support to scale these solutions across regions.

Why This Matters: Sustainability and the Circular Economy

The significance of these efforts goes beyond business efficiency. Textile waste is one of the fastest-growing waste streams globally, and India, with its vast textile industry, has both a problem and an opportunity. According to data from various textile waste studies, more than 1 million tons of textile waste are generated annually in India, a large portion of which comes from institutional use. Diverting this waste from landfills to recycling facilities reduces environmental damage and conserves valuable resources like water and energy.

Challenges That Still Remain

Despite the innovation and enthusiasm, critical challenges persist. First, the recycling infrastructure in India is fragmented and lacks uniform standards. Second, the market for recycled products needs expansion; end-consumers and brands must be educated to value products made from recycled fibers. Third, policy support can play a critical role in incentivizing large hotel chains, hospitals, and other institutions to partner with recycling initiatives.

A Long Road with Great Potential

The example of Bangalore’s textile recycling system — backed by partnerships, technological adoption, and innovative startups — is a model worth scaling. For this sector to grow sustainably, investment in technology, capacity building for waste management companies, and awareness among institutional waste generators are essential.

The road ahead is long, but with data-driven innovation and strategic investment, India has the potential to become a leader in textile recycling — turning today’s waste into tomorrow’s resource.

Leave a comment