Introduction:

India has emerged as the second-largest phone market in the world, with over 200 million phones sold last year, marking a significant shift from a decade ago when most of them were imported. Can we replicate this success and establish India as a prominent player in various sectors such as electronics, electric vehicles, green energy, chemicals, and textiles. The government’s focus is on reversing the declining share of manufacturing in GDP and fostering $1 trillion in goods exports, while generating employment opportunities for its vast working-age population. However, certain challenges hinder this manufacturing revolution, including land acquisition issues, high logistics costs, automation, and a lack of skilled labor.

Revamping Manufacturing Conditions:

The Indian government has taken several measures to transform the landscape of manufacturing in the country. For instance, it has implemented a combination of high import tariffs on finished phones and production incentives to encourage domestic manufacturing. While this has boosted local assembly, true supply chain indigenization is still a substantial challenge. Estimate indicate that Indian factories add only 18% in value to the electronic devices they assemble for export, compared to 38% in China and 24% in Vietnam. The Indian government needs to focus on enhancing the value addition infrastructure to make the “Make in India” campaign a resounding success.

Advantages and Challenges:

Manufacturing in Vietnam has become an attractive option due to low costs and favorable investment conditions. However, India also possesses unique advantages that can propel its manufacturing sector forward. Firstly, India boasts record investments in infrastructure and logistics, which lay the foundation for seamless production and supply chain operations. Secondly, the country’s domestic market offers immense potential, given its sheer size and the rising consumer purchasing power. Lastly, the recent “China plus one” phenomenon, where global corporations diversify their supply chains to mitigate geopolitical risks and the slowdown in China’s economy, presents India with an opportunity to attract foreign investment.

Addressing Key Challenges:

Land acquisition problems have historically plagued India’s manufacturing sector, with issues related to delays, legal battles, and public protests. To alleviate this challenge, the government introduced the concept of land pooling, enabling industries to directly purchase land from farmers. Additionally, greater transparency and procedural reforms could streamline the process and incentivize industrial growth. Furthermore, high logistics costs have hindered the efficiency and competitiveness of Indian manufacturing. The government has focused on improving logistics infrastructure, including investments in ports, airports, and road networks, to reduce costs and facilitate smoother transportation.

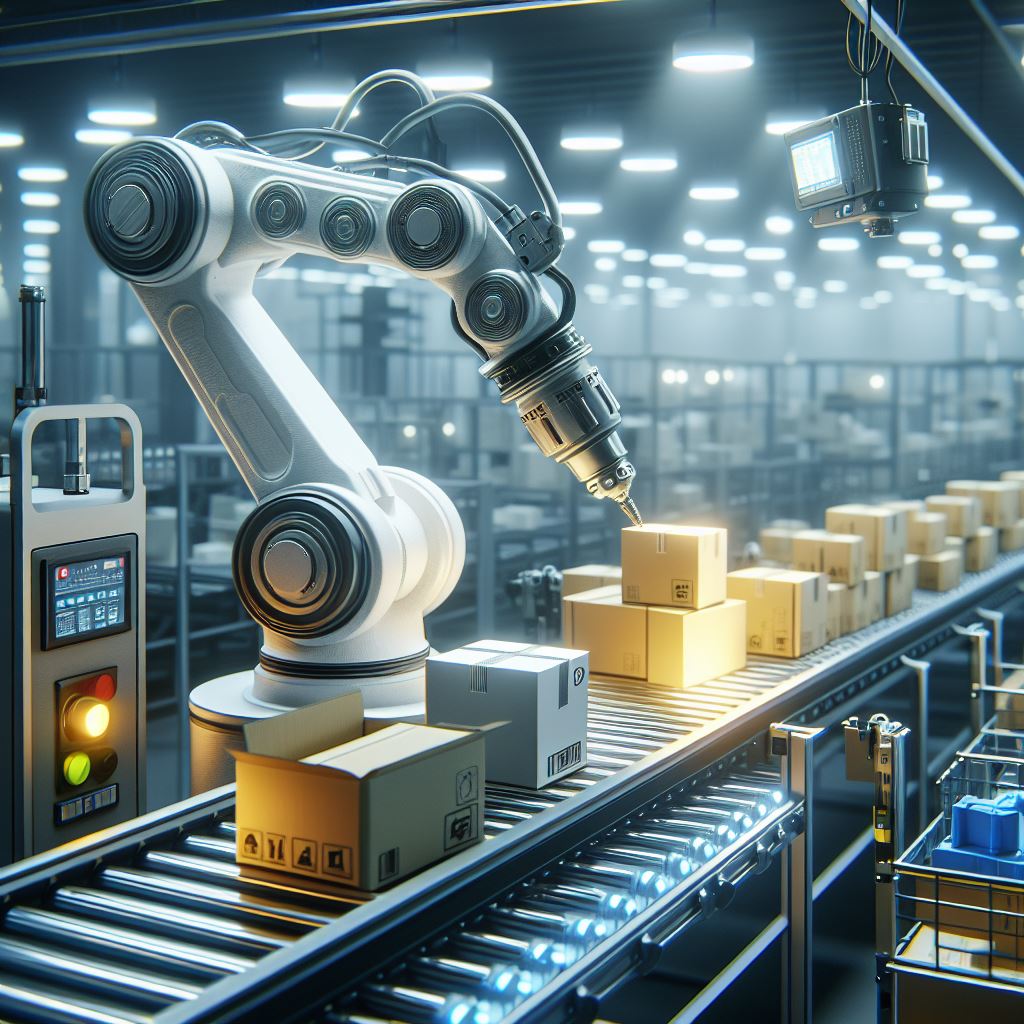

Skilled Labor and Automation:

One of the critical challenges faced by India’s manufacturing sector is the lack of adequately skilled labor. As automation gains prominence, the demand for skilled technicians and engineers continues to rise. To bridge this gap, the Indian government is actively investing in skill development initiatives, vocational training programs, and technical education. Collaborations between industry and academia are also being fostered to ensure a skilled workforce that meets the evolving demands of the manufacturing landscape.

Fostering Innovation and Research:

Building a robust manufacturing sector requires a focus on innovation and research. The Indian government is encouraging indigenous research and development, supporting startups, and offering incentives for innovation. By nurturing a favorable environment for innovation, India has the potential to leapfrog in technology-intensive manufacturing sectors. This will not only enhance the value addition but also establish India as a global leader in cutting-edge manufacturing.

India’s journey toward becoming a global manufacturing powerhouse is marked with immense potential and a set of challenges that need to be addressed strategically. The government’s “Make in India” campaign has seen initial success with the growth of the phone market. To sustain this momentum, India must prioritize value addition, address land acquisition problems, reduce logistics costs, and invest in skill development. By leveraging its record investments in infrastructure, a massive domestic market, and the China plus one trend, India has an opportunity to attract global corporations and position itself as a preferred manufacturing destination. With a focus on innovation and research, India holds the potential to become a factory to the world, generating employment opportunities and propelling economic growth.

Leave a comment