Introduction

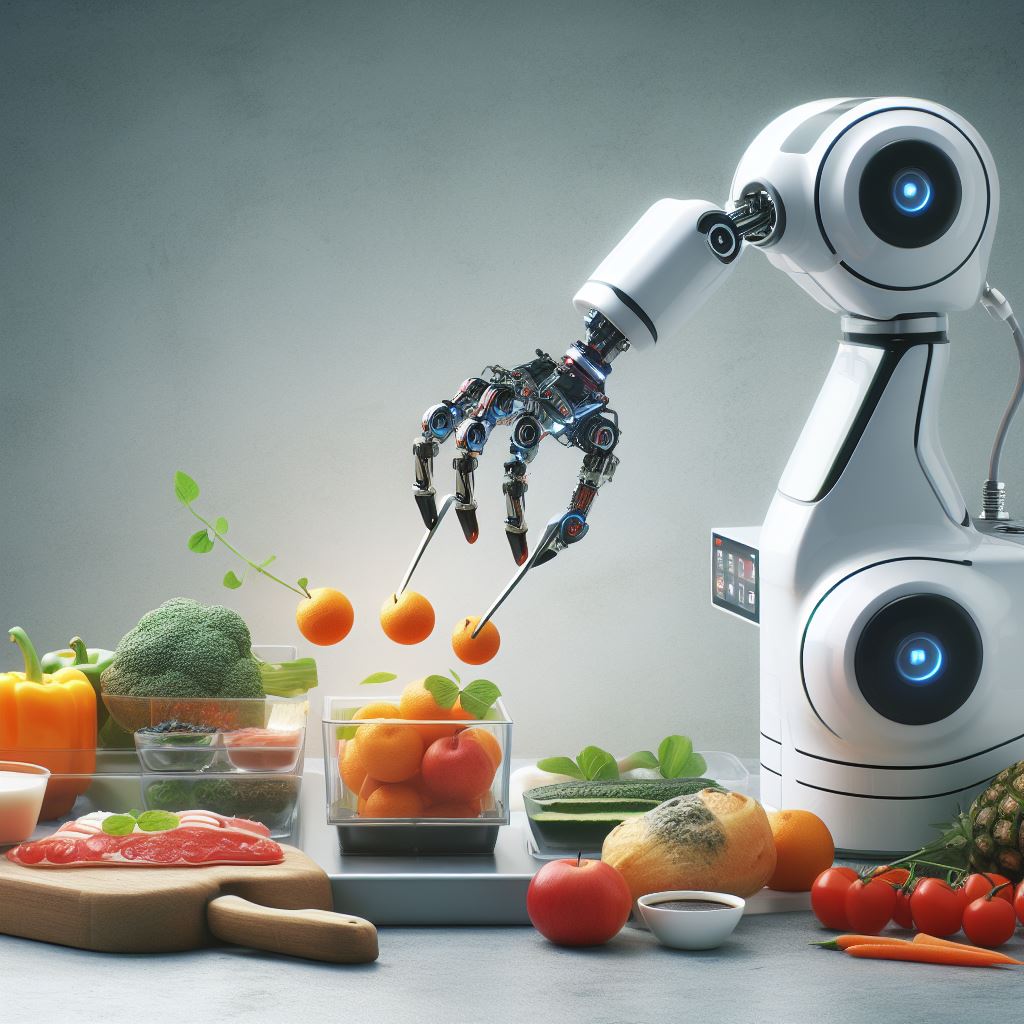

Food robotics is a growing trend in the food industry, involving the use of robots and automation to perform various tasks such as harvesting, processing, packaging, cooking, serving, and delivery[1][2]. This article will explore the benefits of food robotics, including improved productivity, quality, consistency, safety, and hygiene in the food sector[2][3][4][5]. The implementation of robots in the food industry has historically been challenging due to product irregularity and delicate handling needs, but advancements in robotics technology have made it more feasible[1]. As a result, more industry players are adopting food processing robots, leading to a safer, more efficient, and cost-effective sector[1][3].

Benefits of Food Robotics

1. Improved Food Safety and Hygiene

Robots can help control cross-contamination in food processing plants, which is a significant concern for the industry[2]. Unlike human workers, robots don’t get tired, and their pace of work tends to stay consistent, ensuring packaged products are up to company standards[2]. Additionally, modern robotics offer improved sanitary designs, which are essential for preventing contamination in the food supply[3].

2. Increased Productivity and Efficiency

Food processing robots can work much faster than human employees, allowing facilities to sustain higher demand without much disruption[1]. According to a Vantage Market Research report, there is a strong need for increased productivity in food manufacturing, and the Global Food Robotics Market value is expected to reach $3,795.4 million by 2028, growing at a compound annual growth rate (CAGR) of 12.80%[5]. British food tech company OAL is developing robots to automate the ingredient handling and process systems in food facilities, which can weigh out a range of ingredients, making factories more efficient and reducing the amount of staff required for these activities[4].

3. Improved Product Quality and Consistency

Robots work with high reliability, accuracy, and precision, ensuring consistent product quality[2][5]. They can perform a task repeatedly over the course of a workday or shift, typically with minimal deviation in precision, eliminating the need for additional processes such as reworking and sorting[5].

4. Cost-Effectiveness

Implementing robotics in food processing can lead to cost savings for companies. For example, Nestlé’s chocolate manufacturing plants’ productivity increased by 53% after using pallet loading robots[5]. Additionally, robots can free up human workers to focus on tasks of more added value in the factory, further improving cost-effectiveness[4].

5. Attracting Customers

The idea of machines preparing a meal sounds futuristic and can attract clients curious about the technology, boosting sales[1]. For example, there is a restaurant in China that uses more than a dozen robots to cook and deliver food to customers. Robots greet customers, deliver dishes to the table, and cook the food. Each robot can understand 40 everyday sentences and costs about $6,500[3].

Conclusion

Food robotics is a growing trend in the food industry, offering various benefits such as improved productivity, quality, consistency, safety, and hygiene. Despite the historical challenges of implementing robots in the food sector, advancements in robotics technology have made it more feasible. As more industry players adopt food processing robots, the sector will become safer, more efficient, and more cost-effective. Additionally, the use of robots in the food industry can attract customers who are curious about the technology, further boosting sales.

Citations:

[1] 7 Reasons Robots Make a Huge Difference in Food Processing | RoboticsTomorrow https://www.roboticstomorrow.com/story/2023/07/7-reasons-robots-make-a-huge-difference-in-food-processing/20859/

[2] How Food Processors Can Use Robots to Improve Food Quality – FoodSafetyTech https://foodsafetytech.com/column/how-food-processors-can-use-robots-to-improve-food-quality/

[3] Robotics on the Rise in the Food Industry – IFT.org https://www.ift.org/news-and-publications/food-technology-magazine/issues/2017/october/columns/processing-robotics-food-beverage-processing-foodservice

[4] Robots can boost accuracy, efficiency and quality of ingredients handling, says OAL https://www.foodnavigator.com/Article/2019/06/12/Robots-can-boost-accuracy-efficiency-and-quality-of-ingredients-handling-says-OAL

[5] How Robot Implementation Impacts Manufacturing Plant Productivity https://locusrobotics.com/robots-manufacturing-productivity/

[6] (PDF) Improving Productivity:: A Review of Robotic Applications in Food Industry https://www.researchgate.net/publication/308042650_Improving_Productivity_A_Review_of_Robotic_Applications_in_Food_Industry

Leave a comment